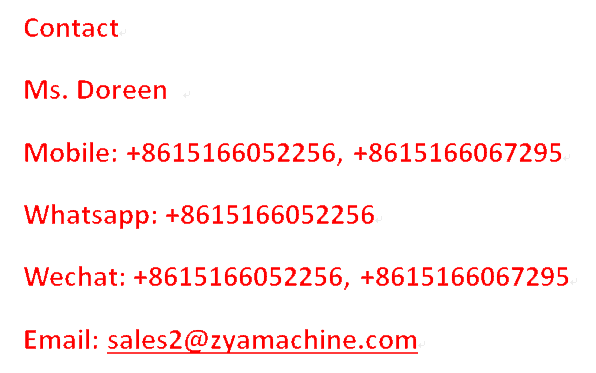

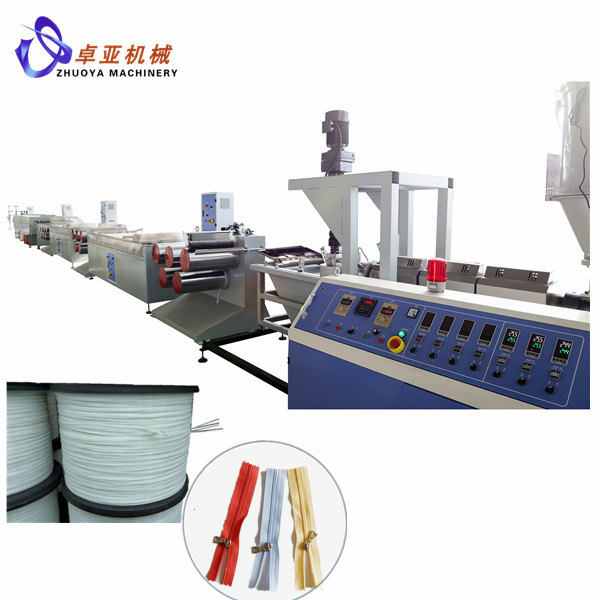

Plastic zipper filament making machine can produce PET PA Nylon monofilament which will be processed into many kinds zipper products for clothes, tents, waterproof shoes, luggage and many waterproof products. The production line is automatic operation from raw material drying to final winding.

We supply several different models according to different raw materials and productivity requirements as following.

>>Model Parameters

| Model | ZYLS-80 | ZYLS-90 | |

| Screw L/D | 30:1 | 30:1 | |

| Gearbox model | 200 | 200 | |

| Main motor | 22/30kw | 30/37kw | |

| Capacity (kgs/h) | 100-125kgs | 125-140kgs | |

| Mould Dia. | 200 | 200 | |

| Filament Dia. | 0.18-2.5mm | 0.18-2.5mm | |

|

Machine Line General Configuration List |

|||

|

No. |

Machine Name |

||

|

1 |

Single screw extruder | ||

|

2 |

Die head + spinnerets | ||

|

3 |

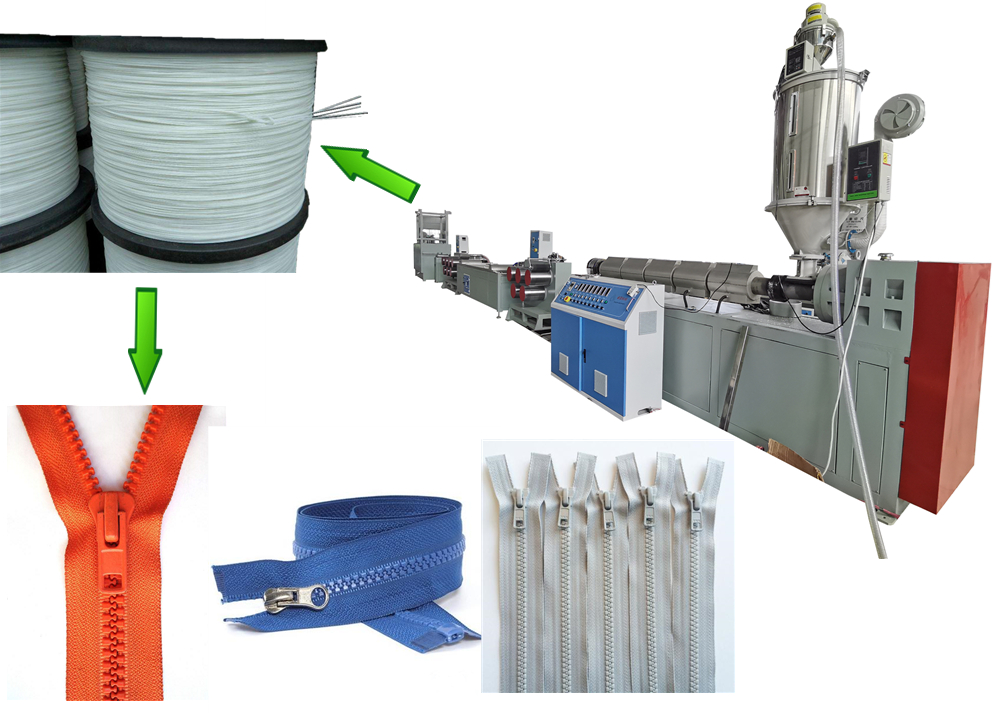

Water trough calibration system | ||

|

4 |

Tensile unit | ||

|

5 |

Hot water tank | ||

|

6 |

Tensile unit | ||

|

7 |

Hot air oven | ||

|

8 |

Tensile unit | ||

|

9 |

Oil coating machine | ||

|

10 |

Winding machine | ||

>>Features

1. Reasonable machine line design according to requirements

2. Customized production line from design to manufacture

3. Production process with mature technology support.

4. High quality filament assurance.

5. Leading position in this field

6. Worldwide clients with good reputation

7. Win-win cooperation with all our partners

>>Plastic zipper filament making machine

Q: Are your company manufacturer or trading company?

A: We are manufacturer.

Q: Can we send sample for customizing the machine line?

A: Yes, we will design and supply customized machines according to your samples.

Q: Can we visit your factory to see runing production line?

A: Yes, we can arrange you to see our runing production line to understand better of our machine line.

Q: If we have any problem of the running machine line, how we solve it?

A: We have comprehensive after-sales service policy which will help you to solve the problem in time.